The Intricacies and Importance of Diecasting in Fashionable Manufacturing

Diecasting is a sophisticated manufacturing method that plays a vital role in creating complicated metal components that have the highest precision and reliability. It involves the injection of molten metal into a mold cavity with high pressure making it possible to create detailed shapes and intricate designs that are difficult to accomplish using other methods. Diecasting is widely used across different industries, such as automotive, aerospace, electronics and other consumer goods because of its high efficiency as well as its ability to make quality parts. This article examines the intricacies of diecasting, highlighting its processes, benefits as well as applications.

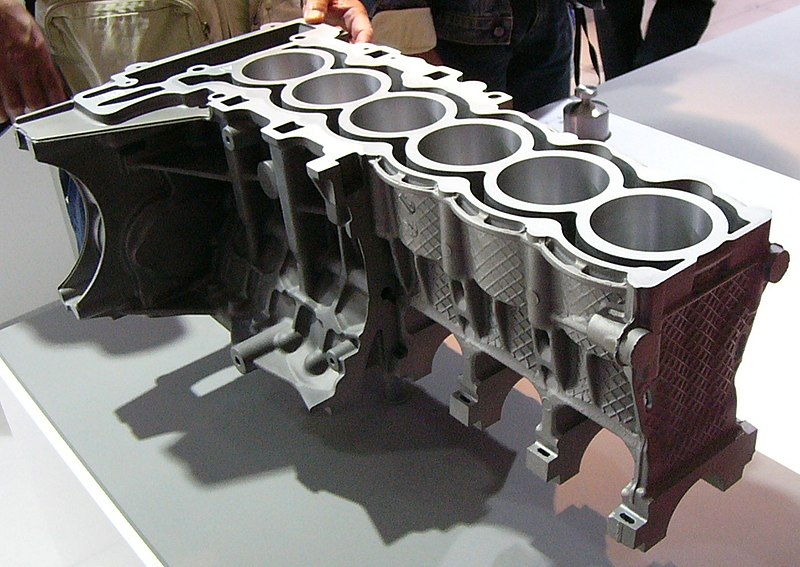

Diecasting begins with the preparation of high-quality steel molds, also known as dies. These molds are created for the harsh pressures as well as the high temperatures produced by molten steel. The dies are meticulously designed to take in intricate details and maintain tight tolerances, and ensure that each part conforms to specific specifications for design. During the casting process, metals such as aluminum, magnesium, zinc and copper are heated and introduced into the die cavity at high pressures. Rapid injections and cooling creates parts that exhibit excellent dimension stability as well as a smooth top finish. Precision of the dies permits the making of components with complex geometries typically impossible using other processes of manufacture.

One of the main benefits of diecasting is its capability to create parts that have exceptional dimensional accuracy and smooth finishing on surfaces. This is because high-pressure injection makes sure that each and every aspect of the mold has been replicated which results in components which meet the strictest tolerances and need minimal or any post-production effort. This precision is particularly advantageous when creating intricate geometries or small details that would be difficult to attain in other manufacturing methods. Furthermore, the ability to repeat diecasting makes it ideal for production on a large scale, as it ensures that the exactness of thousands of pieces. Diecasting's efficiency also leads to significant cost savings since it helps reduce waste materials as well as labor expenses.

The wide range of applications for diecasting is evident in its widespread use across various industries. In the auto industry such as the automotive industry, diecast parts are fundamental in the manufacturing of engine components, transmission housings, and other structural parts. They benefit from the strength and durability provided by diecasting, as well for the capacity to manufacture components that are lightweight, which can improve performance of the engine. in the aerospace field it is essential to have high-strength, lightweight components is critical, and diecasting provides the quality and precision that are required in these types of demanding projects. Electronics for consumer use also depend heavily on diecasting in order to produce high-quality and durable housings as well as internal components to ensure the reliability and longevity of devices. Telecommunications, medical, as well as power tools industry highlight the numerous applications and value of diecasting in contemporary manufacturing. To find new information please look at Senadiecasting

Diecasting's capabilities extend to its many applications in various sectors. In the automotive industry, diecast components are integral to the design of engines, transmissions and structural elements, contributing in the creation of smaller, lighter vehicles that are more efficient in fuel consumption. Within the electronics industry Diecasting is employed to manufacture heat sinks, connectors and housings, providing optimal thermal management and longevity for electronic devices. Consumer products also is a beneficiary of diecasting, having applications that span from household appliances to power tools and toys. Diecasting's versatility to different metals as well its ability to produce parts with intricate patterns make it suitable for many different uses, all profiting from the distinctive benefits that diecasting provides.

Diecasting is an essential manufacturing process that enables the production of high-precision, quality metal components across an array of different industries. Its capacity to design intricate designs with high-quality tolerances and smooth finishes makes it indispensable for applications which require precise details as well as consistent high-quality. Cost-efficiency and efficiency of diecasting also make it attractive in facilitating mass production and maintaining high standards. Technology advances, and the demand for reliable sturdy, light, and lightweight components increases, diecasting will remain an integral part of modern manufacturing. It drives improvement and quality in production.